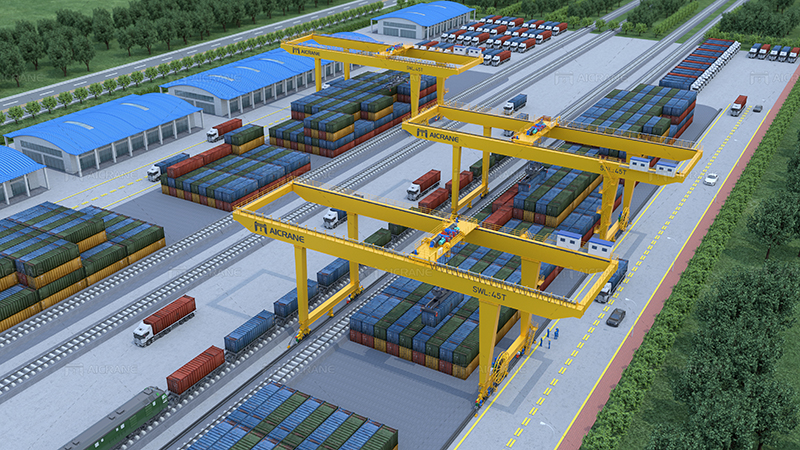

Rail-mounted gantry cranes (RMGCs) play a crucial role in the efficient movement and handling of containers in various industries, particularly in the realm of shipping and logistics. These specialized cranes are designed to operate on rails, providing them with a high level of mobility and precision in handling containers. In this article, we will delve into the types of containers that rail-mounted gantry cranes can handle, exploring their versatility and the impact they have on streamlining container operations.

Understanding Rail-Mounted Gantry Cranes

Rail-mounted gantry cranes are large, sophisticated machines that are commonly used in container terminals and ports. Their primary function is to lift, move, and stack containers with precision and efficiency. Unlike traditional cranes, rail mounted container gantry cranes are mounted on a railway track system, enabling them to traverse the length of container yards seamlessly.

These cranes are equipped with a spreader, a crucial component that facilitates the lifting and positioning of containers. The spreader can be adjusted to accommodate various container sizes and types, making RMGCs versatile in handling a wide range of containers.

Types of Containers Handled by Rail-Mounted Gantry Cranes

Standard Containers (20-foot and 40-foot):

Rail-mounted gantry cranes are designed to handle standard ISO containers, which are the most common in the shipping industry. The two standard sizes are 20 feet and 40 feet, and RMGCs are equipped to lift and move these containers efficiently. The ability to handle standard containers is a fundamental feature that makes RMGCs indispensable in container terminals worldwide.

High Cube Containers:

High cube containers have become increasingly popular due to their extra height, providing more space for cargo. Rail-mounted gantry cranes are designed to handle high cube containers seamlessly. The adjustable spreader allows these cranes to accommodate the additional height of high cube containers, ensuring a smooth lifting and stacking process.

Refrigerated Containers (Reefers):

Refrigerated containers, commonly known as reefers, are equipped with temperature control systems, making them suitable for transporting perishable goods. Rail-mounted gantry cranes are equipped to handle reefers, ensuring the efficient transfer of temperature-sensitive cargo from ships to container yards or vice versa. The precision and speed of RMGCs contribute to maintaining the integrity of the cargo during the handling process.

Open-Top and Flat Rack Containers:

Open-top containers and flat rack containers are specialized types designed to accommodate oversized or unconventional cargo. Rail-mounted gantry cranes are versatile enough to handle these non-standard containers, thanks to the adaptability of their spreader systems. This capability makes RMGCs invaluable in handling a diverse range of cargo types beyond standard dimensions.

Tank Containers:

Tank containers, commonly used for transporting liquids, are another type that container gantry cranes can handle. The spreader can be adjusted to securely lift and move tank containers, providing a reliable solution for the efficient transfer of liquid cargo in and out of ports and terminals.

Specialized Containers:

Beyond the common types mentioned, rail-mounted gantry cranes can also handle specialized containers designed for specific purposes, such as those used for transporting automobiles, chemicals, or oversized machinery. The adaptability of RMGCs makes them suitable for a wide array of containerized cargo.

Conclusion

Rail-mounted gantry cranes stand at the forefront of container handling technology, providing a versatile and efficient solution for the movement of containers in ports and container terminals. Their ability to handle various container types, including standard, high cube, refrigerated, open-top, flat rack, tank containers, and specialized containers, underscores their significance in the global logistics and shipping industry.

As containerized cargo continues to be the backbone of international trade, the role of rail-mounted gantry cranes becomes increasingly vital. Their ability to adapt to different container types not only enhances operational efficiency but also contributes to the seamless flow of goods across the supply chain. As technology advances, we can expect further innovations in gantry crane design, further expanding their capabilities and solidifying their place as indispensable assets in the world of container handling.