Marine hydraulic winch systems have long been integral components in various maritime operations, from offshore construction and vessel mooring to towing and anchor handling. These powerful systems rely on hydraulic mechanisms to provide the force necessary for lifting, pulling, and positioning heavy loads in the challenging marine environment. With the advent of automation and remote control technologies, there’s a growing interest in whether marine hydraulic winch systems can be automated or remotely controlled to enhance efficiency, safety, and operational capabilities. Let’s delve into this topic further to explore the possibilities and implications of automating hydraulic winch systems in the marine industry.

Understanding Hydraulic Winch Systems:

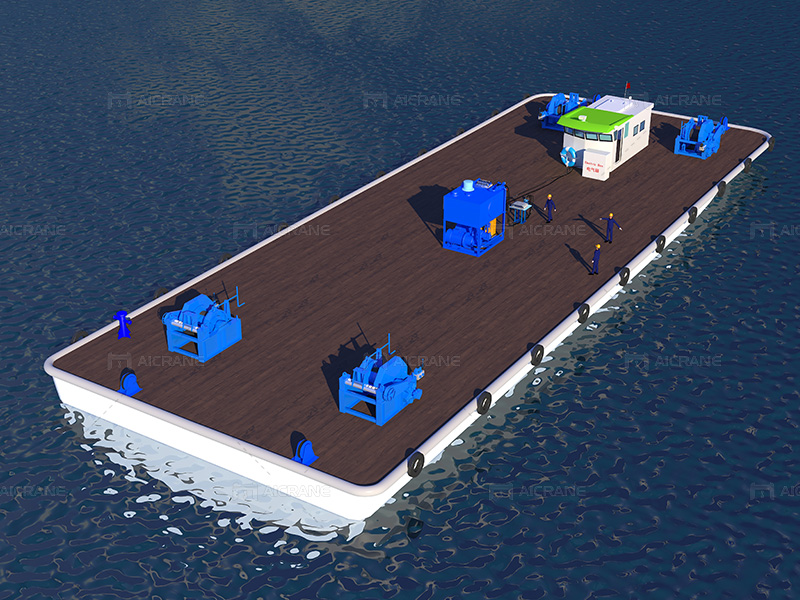

Before delving into automation possibilities, it’s essential to grasp the fundamentals of marine hydraulic winch systems. These systems utilize hydraulic power to operate the winch, typically driven by a hydraulic motor that converts hydraulic pressure into mechanical force. Hydraulic winches offer several advantages over other types, including high power-to-weight ratio, precise control over speed and torque, and suitability for heavy-duty applications. They are commonly used in marine vessels, offshore platforms, and port facilities where robust and reliable winching capabilities are paramount.

Automation in Marine Operations:

Automation has been revolutionizing various industries, including manufacturing, transportation, and agriculture, by enhancing efficiency, productivity, and safety. In the maritime sector, automation technologies are increasingly being adopted to streamline operations, reduce human error, and optimize resource utilization. From automated cargo handling systems in ports to unmanned surface vessels for oceanographic research, automation is reshaping the way maritime activities are conducted.

Automating Hydraulic Winch Systems:

The question arises: Can marine hydraulic winch systems be automated or remotely controlled? The answer is yes, with the right technology and integration. By incorporating sensors, actuators, and control systems, hydraulic winch systems can be automated to perform specific tasks without direct human intervention. These automation capabilities offer several potential benefits in marine operations:

Precision and Accuracy: Automated hydraulic winch systems can achieve precise and accurate positioning of loads, thanks to advanced control algorithms and feedback mechanisms. This level of precision is particularly crucial in delicate operations such as subsea construction, where exact positioning is required to avoid damage to underwater structures.

Remote Operation: Remote control capabilities enable operators to control hydraulic winch systems from a safe distance, whether onboard the vessel or from a shore-based control center. Remote operation enhances safety by minimizing exposure to hazardous conditions and allows for continuous monitoring and adjustment of winching parameters.

Integration with Marine Systems: Automated hydraulic winch systems can be seamlessly integrated with other marine systems, such as dynamic positioning systems (DPS) and vessel management systems (VMS), to optimize overall vessel performance and efficiency. Integration enables coordinated control of multiple systems, leading to smoother and more efficient operations.

Reduced Workload: Automation reduces the workload on crew members by automating repetitive tasks and minimizing the need for manual intervention. This frees up personnel to focus on higher-level tasks, such as monitoring overall operations, troubleshooting issues, and making strategic decisions.

Safety Enhancement: Automation enhances safety by reducing the risk of human error and minimizing the likelihood of accidents during winching operations. Automated systems can incorporate safety features such as overload protection, emergency stop functionality, and fail-safe mechanisms to mitigate potential risks.

Challenges and Considerations:

While the potential benefits of automating hydraulic winch systems are evident, several challenges and considerations must be addressed:

Reliability and Redundancy: Automated systems must be highly reliable and include redundant components to ensure continued operation in the event of component failures or system malfunctions. Fail-safe mechanisms and backup power sources are essential to maintain operational integrity.

Environmental Factors: Marine environments present unique challenges, including exposure to saltwater, extreme temperatures, and rough seas. Automated hydraulic winch systems must be designed to withstand these harsh conditions and operate reliably in challenging environments.

Regulatory Compliance: Adoption of automation technologies in the maritime industry must comply with relevant regulations and standards governing vessel operations, equipment safety, and crew qualifications. Regulatory bodies play a crucial role in ensuring that automated systems meet stringent safety and performance requirements.

Training and Skill Requirements: Crew members responsible for operating and maintaining automated hydraulic winch systems require specialized training and skill sets to effectively utilize the technology. Training programs should focus on familiarizing personnel with system operation, troubleshooting procedures, and emergency response protocols.

Future Outlook:

The integration of automation and remote control technologies into marine hydraulic winch systems represents a significant advancement in maritime operations. As technology continues to evolve, we can expect further innovations in this field, including enhanced autonomy, predictive maintenance capabilities, and integration with emerging technologies such as artificial intelligence and machine learning. Ultimately, automation has the potential to revolutionize the way marine winch systems are utilized in the marine industry, driving improvements in efficiency, safety, and operational performance.

In conclusion, marine hydraulic winch systems can indeed be automated and remotely controlled, offering numerous benefits in terms of precision, safety, and operational efficiency. While challenges exist, continued advancements in technology and regulatory frameworks are paving the way for widespread adoption of automated winching solutions in the maritime sector. By embracing automation, the industry can unlock new opportunities for innovation and productivity in marine operations.